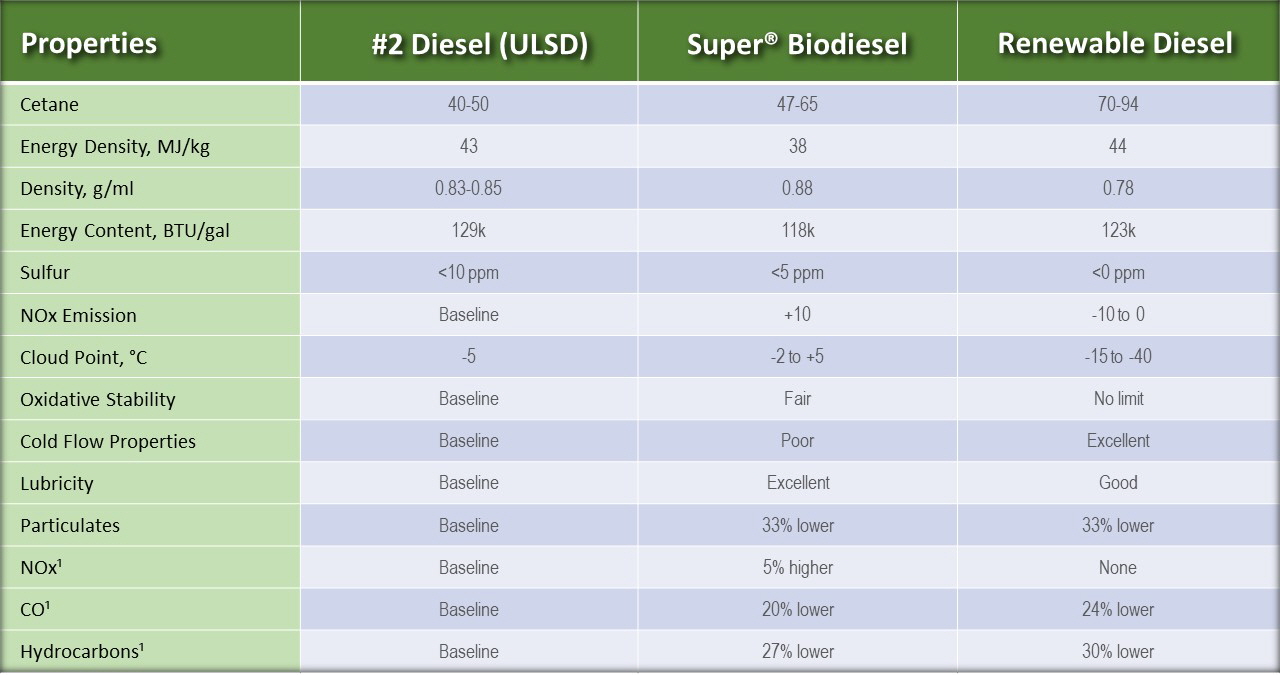

- Renewable hydrocarbon diesel (RHD), or simply Drop-In Diesel, is diesel fuel hydrotreated from biomass oils and animal fats

- RHD uses same feedstocks as biodiesel, but has different fuel properties

- Emits 80% less emissions than ULSD with almost zero NOx

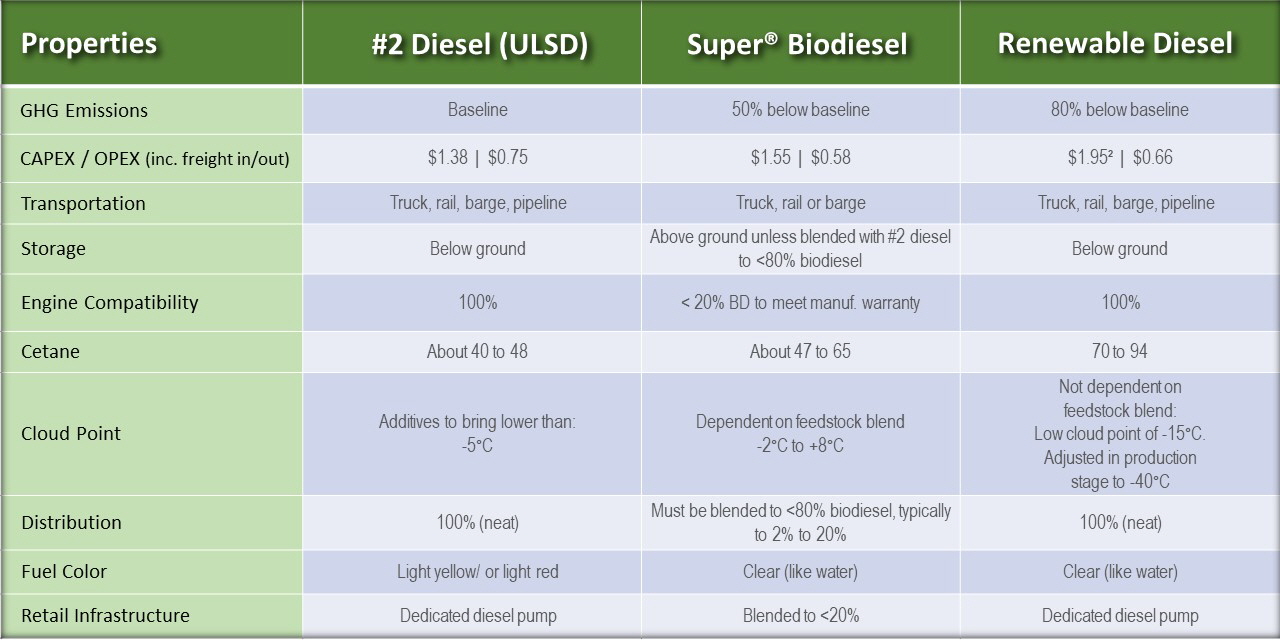

- RHD should be used neat to take advantage of its properties.

- It can be blended with Petro-diesel (#2 diesel), but blending in 5% Biodiesel to increase lubricity makes a better choice

- Engine warranties same as #2 diesel (by comparison the, maximum Biodiesel blend for warranty is 20%)

- Logistics are exactly the same as for ULSD - from Producer to Storage to Retail Pumps including Pipelines (Biodiesel and Ethanol can NOT use pipeline)

- City fleets using RHD include: Oakland, San Diego, San Francisco and LA among many municipalities in California

Renewable Diesel Basics

Low Cost Feedstocks, Up to100% FFA,

Produce High Quality Renewable Diesel

The cost to a renewable diesel or biodiesel producer for trap grease, with FFAs running anywhere from 35% to 90%, typically costs less than half that of typically used feedstocks such as yellow grease, used cooking oil and corn oil.

Municipalities across the U.S. contract with approved vendors to pick up the grease. These entities process the material ready for biofuels production use. The material is approved for use as biodiesel or renewable diesel by the EPA under the Renewable Fuels Standard (RFS) and by the California Air Resources Board’s Low Carbon Fuel Standard (LCFS).

There are two general categories of waste oil and grease. The cleanest and easiest to work with is used cooking oil, also called waste vegetable oil or used fryer oil. This is edible oil that has been used multiple times in a deep-fat fryer. The second type is called “trap grease.” Restaurants are required to install grease traps in their drains to prevent fats and oils that go down the drain from entering sewer pipes. The grease in these traps can be collected to make biodiesel.

While oilseed feedstocks originate in rural areas, used oil and grease are urban resources. The processing costs for waste oil and grease are higher per gallon than the processing costs for virgin vegetable oil. However, the cost of the feedstock is generally low and sometimes free.

The main challenge to biodiesel production from used oils and greases is the high percentage of free fatty acids (FFAs) in the feedstock. Fats and oils are composed of triglycerides – three fatty acid molecules attached to a glycerol molecule. In used oils and greases, some of the triglycerides have broken down so that the fatty acids are separated from the glycerol molecule. These are called free fatty acids. These free fatty acids tend to react with the alkali catalyst in biodiesel production to form soap instead of biodiesel. This reduces the level of free catalyst and thus reduces the speed of the transesterification reaction. Soap formation tends to inhibit the separation of the ester from the glycerin and slow down the reaction. In addition, because the soap must be removed and discarded, more soap formation means less biodiesel.

Used grease with less than 15% FFAs is called "yellow grease." Used grease with more than 15% FFAs is called "brown grease."

Feedstock, The life-blood of the Biofuels Industry (studies)

Trap grease is retrieved from special equipment in the sewer lines from restaurants and other locations. Used cooking oil is saved in receptacles connected inside the kitchen of restaurants.

Click on image at left for white paper on availability of low cost feedstocks by selected city in the U.S.

Renewable Diesel Basics

High Performance

RHD has a high cetane number of 70-95 which ensures the fuel is efficient and clean combustion. With a higher cetane than #2 Diesel or biodiesel, the fuel provides easier starting and less engine noise.

Superior Cold Weather Performance

Regardless of the feedstock used, the RHD fuel will exceed both #2 diesel and biodiesel “cloud points,” (the temperature the fuel begins to cloud and eventually clog the fuel filter). RHD cloud point is -15C compared to #2 diesel at -5C. and biodiesel at a range of -2C to +10C depending on the feedstock used,

Environmentally Friendly

RHD reduces greenhouse gases and particulate emissions by about 80% to 90% compared to #2 diesel. By comparison, Biodiesel is about 60% cleaner than #2 diesel.

Fuel Distribution

100% compatible with the existing infrastructure, is handled exactly the same as #2 diesel.

Long Shelf Life

The product contains no oxygen and therefore no oxidation so can be stored for long periods with no deterioration in quality or increase in water contamination.

Same Nomenclature As #2 Diesel

RHD’s chemical composition is the same as #2 diesel (but with added characteristics mentioned above). In fact its ASTM designation is the same as #2 diesel, ASTM D975.

Odorless

RHD contains no oxygen, sulfur or aromatics.

Notes 1: The baseline is for #2 ULSD diesel fuel

2: Assumes taking hydrogen from the pipeline or stranded at a chemical plant.

If hydrogen is manufactured from natural gas on site (with a Steam Methane Reformer) about a 50% to 75% capex increase.

Click on image at left for white paper on the difference between Biodiesel and Renewable Diesel

Click on image at left for a Piedmont Biofuels Study on how municipalities manage trap grease pick up including its economics

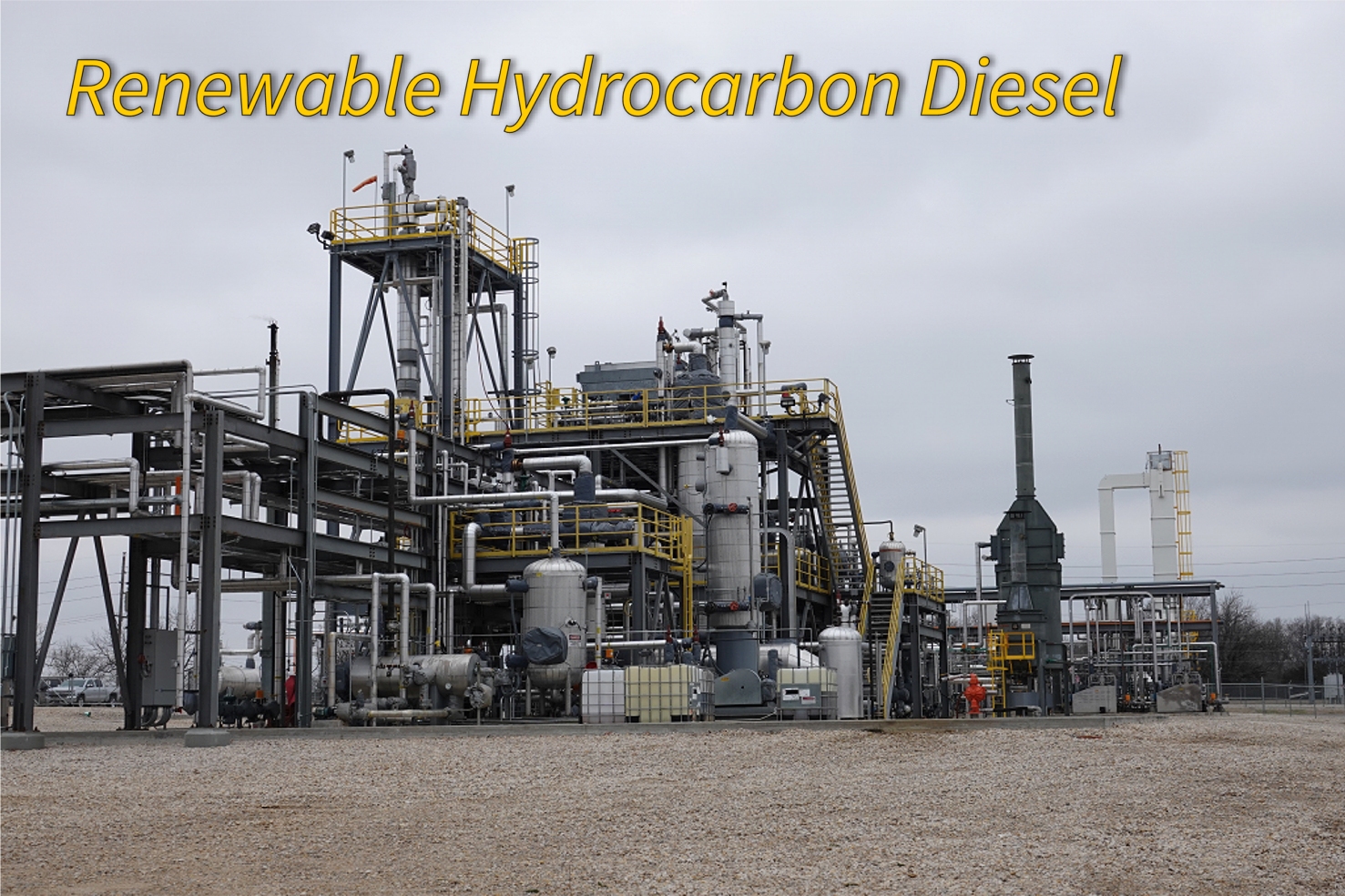

(Above) 5MMgy renewable diesel plant owned by East Kansas Agri-Energy. Commissioned in December 2016

(Above) 5MMgy renewable diesel plant owned by East Kansas Agri-Energy. Commissioned in December 2016. Technology patented and under license.

Copyright 2020 Jatro Renewables, Inc. | 845 North Main Street,

Miamisburg (Dayton), OH 453422

(937) 308-1230

www.JatroRenewables.com