Supercritical Biodiesel

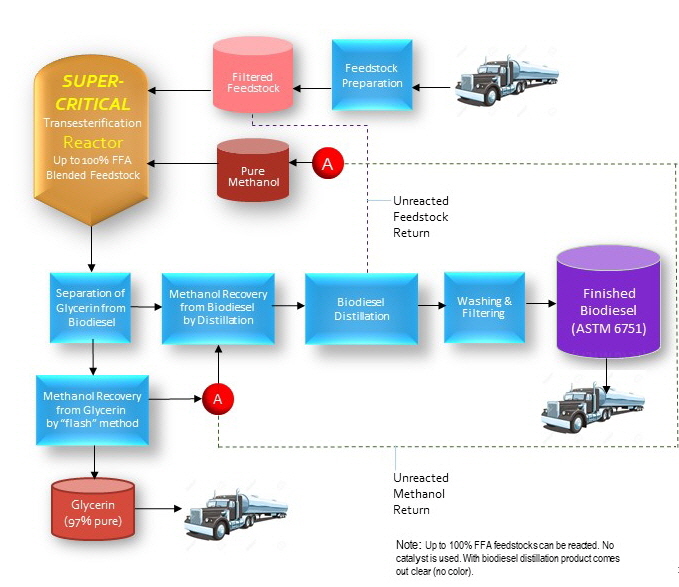

The Supercritical (Super™) biodiesel process is patented and was developed by Jatro Renewables over a two year period.

The process differs substantially from “traditional” methods of producing biodiesel in that it uses no catalyst and is able to process up to 100% free fatty acid (FFA) feedstocks.

The process is also easy to operate as without the catalyst no soap can form eliminating the clean-up labor and system down time cost.

Also, by not needing a catalyst, the by-product glycerin (8-11% of total production) is worth about double the value of glycerin produced at traditional biodiesel facilities.

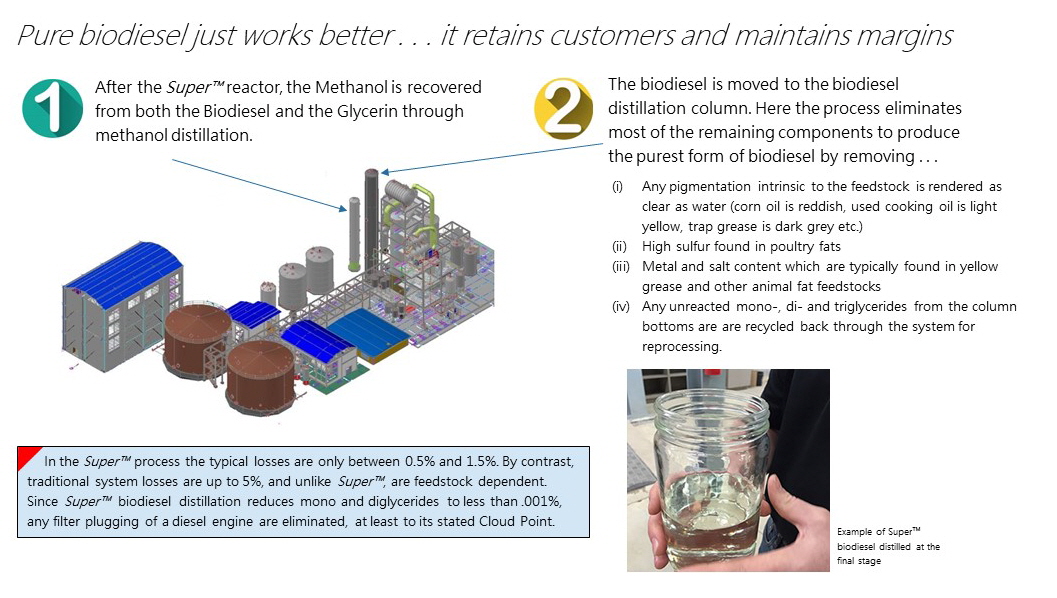

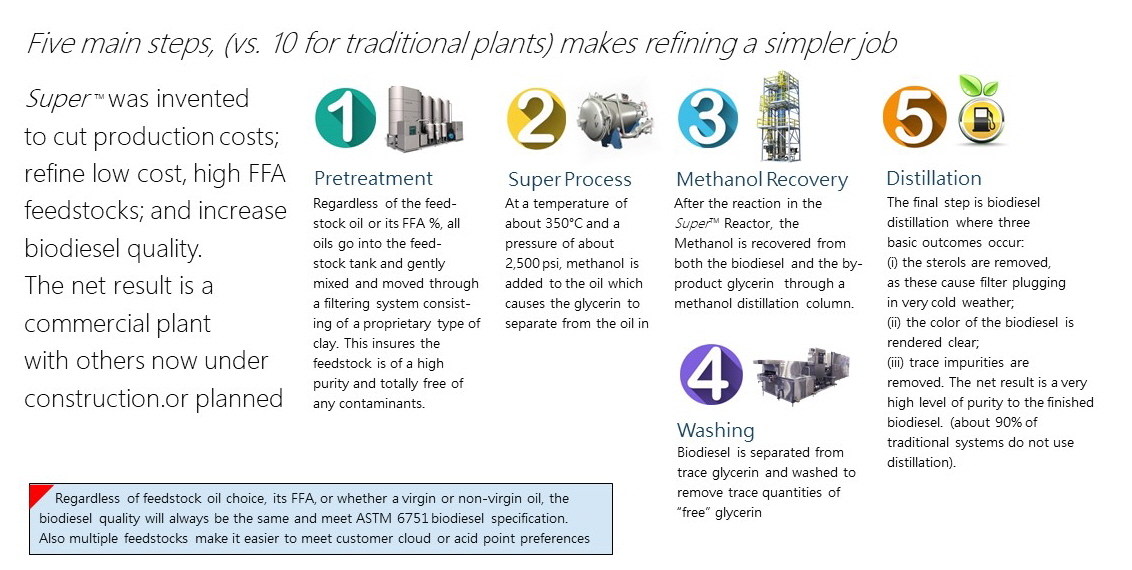

The Super™ process reacts the feedstock and methanol at approx. 700C. and under about 2,700 psi pressure.

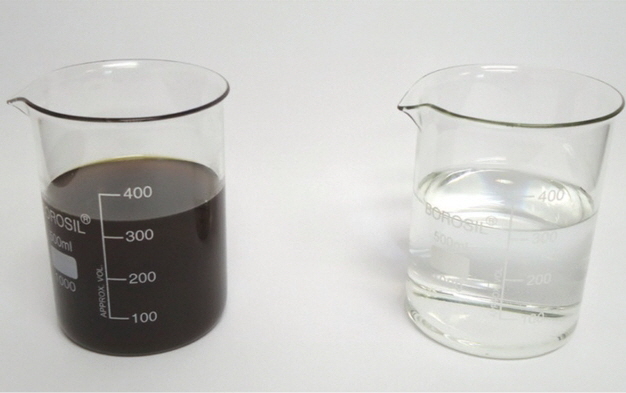

Final distillation removes sterols and metal contaminates and renders the biodiesel perfectly clear.

Left, typical color of a mixed feedstock of yellow grease, used cooking oil and corn oil. Right, clear biodiesel produced using Jatro Renewables Super™ process

Increasingly retail car and truck stops offer a range of biodiesel blend options to customers

- All equipment is typical for an industrial process

- Using a proven design ensures maximum equipment reliability and product quality

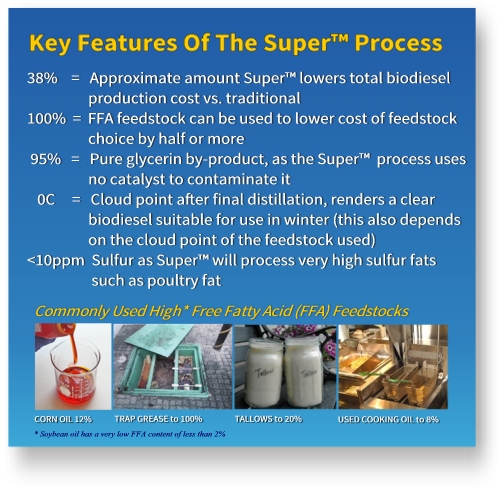

- Up to 100% FFA feedstock can be refined into biodiesel.This provides use of low cost and off-spec. feedstocks

- No use of catalyst to deteriorate quality of glycerin

- Without catalyst, no possible soap formation which saves time, labor and clean-up cost

- Gravity separation of methyl ester from glycerin

- Feedstocks can be mixed together for processing regardless of FFA or type

- Very light water washing so small discharge as a waste stream (gray water)

- Final distillation removes sterols and any metals and other contaminates

- Final product is clear so will not discolor existing of #2 diesel when blended.

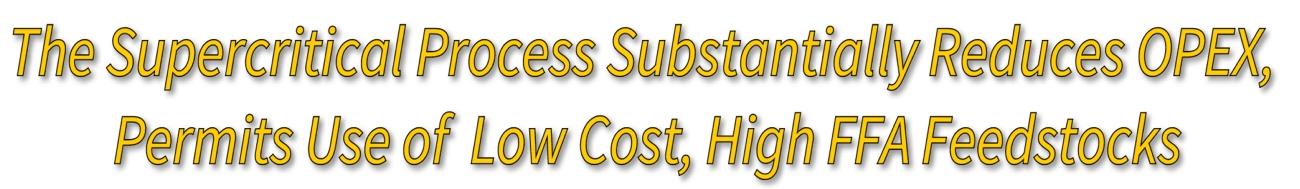

The Process Advantage

Click graphic for pdf about how Supercritical technology over Traditional methods of producing biodiesel can give you a significant competitive edge.

DIESEL RULEMAKINGS

AUTOMATIC/MANUAL Automated

SHIFTS

3 shifts of 8 hours or 2 shifts of 12 hours each

OPERATORS and PERSONNEL PER SHIFT

5 to 10 mmgy plants: 1 to 2 Operators, 1 Chemist; 1 to 3 assistants for maintenance/load/unload etc. (Additional personnel for 30 to 50 mmgy)

TYPE OF EMPLOYEES

Operators, Utility Personnel, Chemists, Bookkeepers, Sales and Management.

PROJECT ESTIMATE Estimates include: Working Capital - Civic/Bldg/Land

5 mmgy: $16,438,607 ($3.28/nameplate gal.) $1.00m $0.00m

10 mmgy: 19,946,701 ($1.99 “ “ ) 2.75m 0.00m

15 mmgy: 23,795,333 ($1.58 “ “ ) 3.00m 0.00m

30 mmgy: 36,989,852 ($1.24 “ “ ) 6.00m 0.00m

50 mmgy 53,000,000 ($1.06 “ “ ) 10.00m 0.00m

The above includes land, building, roads, capital for feedstock and chemicals.

Projects well ahead of expectations, deduct ~5% of plant cost estimate.

The final cost estimate will vary depending on a number of factors; however,

we have built into the estimates contingencies to minimize coming in over budget..

PROJECT TIME-LINE

10 to 15 months from contract signing date to plant commissioning, EPA

and LCFS (for California and Oregon), registration of ASTM 6751-15 biodiesel production and fuel pathway approvals.

WARRANTY

All equipment that is part of the project covered by vendors’

warranties which typically range from 60 days to 5 years or more.

Warranty starts when the equipment is received on-site.

Additional warranty can be bought directly from vendors

PROCESS WARRANTY

Quality: Biodiersel, ASTM 6751-15. Renewable Diesel, ASTM D975

Volume: 10 to 90 gpm (or 50 to 500 mt/day)

YIELD

>98.5% (guaranteed, based on feedstock quality).

ENGINEERING & LICENSING

1. Designing and permitting of the entire facility (including equipment,

tank farm placement, pipeline layout etc.)

2. Working with customer’s civil engineering firm to design the

plant building structure (if required), roads and rail

3. Managing the project with plant manager for mechanical, electrical

and automation coordination

4. Soliciting one or more quotes for certain equipment

5. Provide PFDs, simulation data (ChemCAD), P&IDs, and 3D drawings

for entire facility

6. Operational manuals in the form of “functional requirement.” This

includes: process description, operational logic and start and stop

procedures. (Typically, each facility has specific requirements for

company manuals)

7. One-time licensing fee (included in figures above).

Jatro Renewables Typical Plant Cost Overview

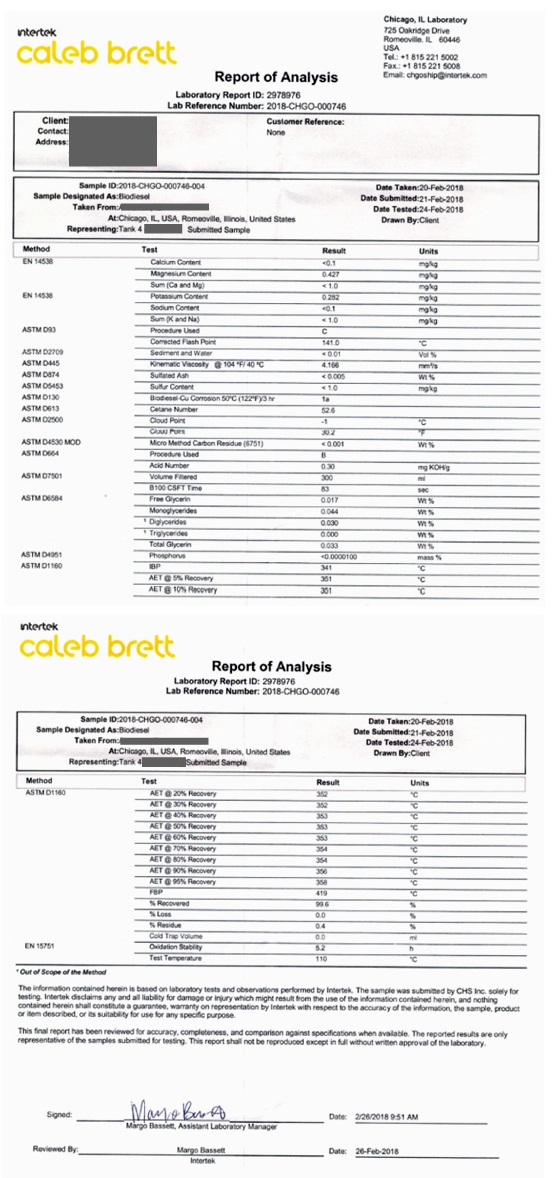

Certificate of Analysis (Typical)

A typical chemistry lab will test about six of the required 18 test s for ASTM 6751, and for each batch of fuel. The balance of analysis is sent out to a 3rd party lab on a regular basis, but not for every fuel truck or rail car load leaving the plant (see below).

SUMMARY

The total cost of the project (as listed above) includes the estimated costs for the land, building/structure, building modifications/improvements, insulation, grounding, pump pads, storage containment walls, and any outside additions such as laying of the road or a rail line (with certain limitations). It also, includes the total all-in project costs for the Process Equipment, including Storage tanks and all Labor.

Jatro Renewables suggests using a local engineer or a permitting consultant to work with the local environmental or regulatory agency.

With our prior experience in implementing projects in various states in the U.S (MI, OH, NE, IL, NY, PA, MD, WI, and CA) as well as outside the U.S, we can provide guidance on the engineering, and permitting issues from EPA and other local regulatory bodies on both process equipment and electrical/automation instrumentation.

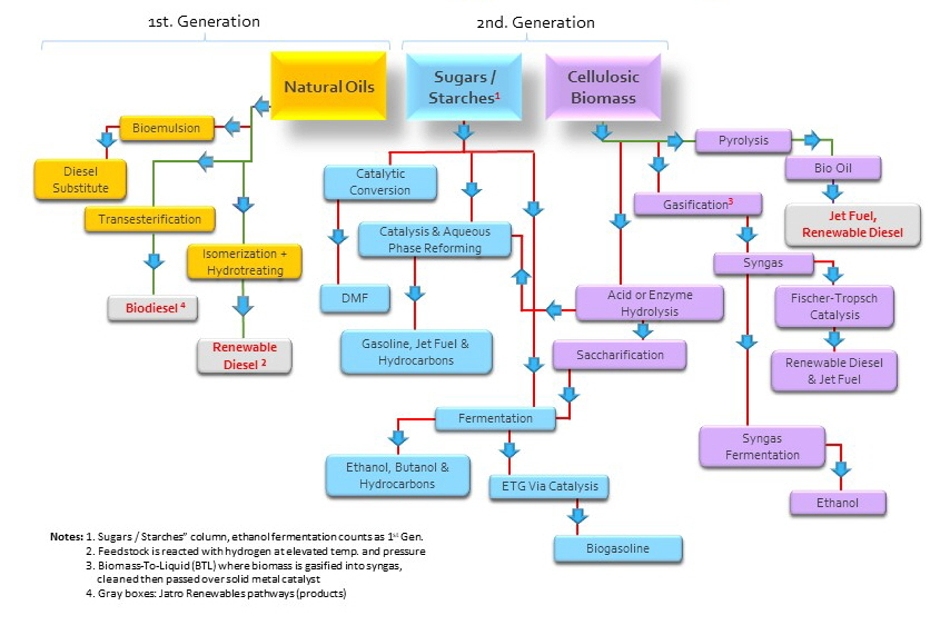

Currently, Jatro Renewables has two genres of plants it offers clients:

- Supercritical technology-based transesterification of virgin oils and

animal fats into biodiesel (ASTM 6751-15).

- Renewable Hydrocarbon Diesel (D975) using hydroprocessing

techniques of virgin oils and animal fats.

Within about three years, new and existing Supercritical and RHD plants will use oils from cellulosic materials such as woody biomass, grasses and municipal solid waste.

These oils will be provided by 3rd party sources or from equipment supplied by 3rd party vendors. It is not anticipated any major design changes to existing or new plants will be required.

Jatro Renewables Technology Development

Click to enlarge

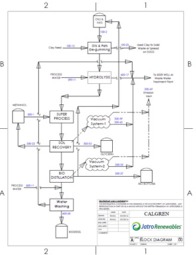

Block Diagram of Supercritical Plant

Click to enlarge

Since the advent of the internet and loss of newspaper subscription and greatly reduced 1st Class Mail use, the paper industry are looking to other industries to replace use of their feedstock, trees. Use of paper is down about 60% since 1998 . . . and still shrinking.

Biodiesel Chemist taking a biodiesel sample for analysis at certain points in the production line

Click to enlarge

Copyright 2020 Jatro Renewables, Inc. | 845 North Main Street,

Miamisburg (Dayton), OH 453422

(937) 308-1230

www.JatroRenewables.com